You are here: What is Portable Appliance Testing?

Portable Appliance Testing, or PAT testing, checks that the appliances plugged into electrical outlets in a property are safe to use and well maintained. This covers many appliances, such as handheld equipment like stick blenders or hand drills, IT equipment like printers and desktop PCs, large white goods like washing machines and dishwashers and built-in equipment like integrated fridge freezers.

At first glance then, it seems that the term ‘Portable Appliance Test’ is a bit of a red herring, in so much as not all appliances that can be PAT tested are generally thought of as ‘portable.’ To electricians, the term ‘portable’ (i.e., easy to move) here means ‘removable’ to the lay person: if it has a plug top or plugs into a power source, it is ‘portable.’

PAT Test vs EICR

Whereas an Electrical Installation Condition Report (EICR) covers the electrical systems and installations from the point of the incoming power supply to the point where it is used in the property (sockets and switches), a PAT test covers those appliances and pieces of electrical equipment that are plugged into these sockets and switches. Of course, if an electrician saw a clearly dangerous appliance plugged into a socket during an EICR inspection, it would be noted and hopefully dealt with.

Who needs PAT testing?

Electricity at Work Regulations (1989), along with Health & Safety at Work Act 1974 and Managing Health and Safety at Work Regulations 1999, means that if you are responsible for the electrical safety of a property (be it domestic, commercial or industrial) you must make sure your portable electrical equipment is safe. Therefore employers, the self-employed and landlords are responsible for the safety of electrical equipment. It should be noted that the user (employee, tenant etc.) also has a requirement not to use equipment that seems unsafe and use any electrical equipment in a safe way.

The legislation and regulations do not require employers, the self-employed and landlords to have PAT testing done. However, PAT testing is one way to ensure the electrical equipment is safe and in good condition, and it has become commonplace to this end.

Who can perform PAT testing?

There is no formal qualification for PAT testing. The only requirement is that PAT is carried out by a competent person. A competent person is someone with “sufficient technical knowledge or experience to be capable of ensuring that injury is prevented” (Electricity at Work Regulations 1989, pp. 42). Many companies offer PAT testing courses to train individuals who are then made responsible for PAT testing in their workplace. Many electricians also offer this service, particularly if you have an extensive array of appliances to test and keep records of.

What appliances need testing?

The category of the equipment and its electrical classification are the two main determinants of whether an appliance needs testing or not.

Appliances are classified as follows:

Class 1

This is equipment with basic insulation and is therefore reliant on protection from earthing. These require PAT testing.

E.g., desktop computers, toasters, dishwashers.

Class 2

Equipment with double insulated cabling. These do not require testing with calibrated PAT testing equipment, only thorough visual inspection.

E.g., T.V.s, hairdryers, printers

Class 3

These appliances are designed to get power from separate extra low-voltage (SELV) sources. Class 3 items do not need PAT testing, but their charging cables should be tested.

E.g., laptops, mobile phones, torches, cameras.

Portable appliances fit into one of seven categories:

- fixed

- portable

- stationary

- chargers and cables

- movable

- handheld

- IT

So, for example, a handheld drill will not need testing, but its charging unit will.

It is generally advised that brand-new appliances would not need to be tested before first use, however it is always worth doing a visual inspection of a new appliance.

What does PAT involve?

Visual inspection makes up a large part of PAT testing. The electrician will look at the casing, the leads and plug top. They will check for exposed wiring, cracks in the casing and if there are any kinks or damage to the cable insulation. They will also ensure cables have two layers of insulation (looking for the Class 2 equipment symbol pictured). PAT testers will also: open the plug and check the fuse, check each screw and the cord grip for tightness.

Referring to manufacturers’ instructions, good practice or specific risk assessments, the tester should check that an appliance is being used in a suitable environment. For example, is there the necessary ventilation and space for the dissipation of heat around the coils of a fridge freezer? Is the appliance exposed to corrosive or flammable materials, extreme temperatures or weather?

If an appliance has a double insulated cable, it is a Class 2 appliance and does not need to then go on to be tested for polarity, insulation and continuity.

For Class 1 equipment, it is necessary to conduct electrical tests using a PAT testing machine. These test for lead polarity, insulation resistance and earth continuity. This is not suitable or necessary for Class 2 appliances that are double insulated, but most Class 1 appliances should be tested using such a machine.

Fixed Class 1 Appliances

According to PATTA (Portable Appliance Testing Trade Association), there is a grey area in terms of testing Fixed Class 1 appliances (for example integrated kitchen appliances, some hotel hairdryers or hand dryers).

PATTA highlight the fact that the PAT tester is not required to test Fixed Class 1 appliances because they have been wired into the mains supply, and the PAT tester would need to isolate them from the mains supply to test them fully; to do so safely is usually beyond the skill set of an average PAT tester and presents a risk.

However, the employer, landlord or self-employed person is still responsible for making sure such appliances are safe. PATTA therefore recommend that PAT testers should not be encouraged or forced into testing Fixed Class 1 appliances; they should instead conduct thorough visual inspections and advise that a qualified electrician (with the knowledge and skills set, as well as sufficient insurance to cover their work) is employed to test these appliances fully.

Records

It is vital to adhere to a regime of PAT testing to ensure equipment is safe and keep a detailed record of testing, the condition of equipment and results.

Most often, this involves a comprehensive itinerary of all equipment and dates of testing, with space for noting the condition of the equipment and any action or repairs needed, and a date for re-testing in future.

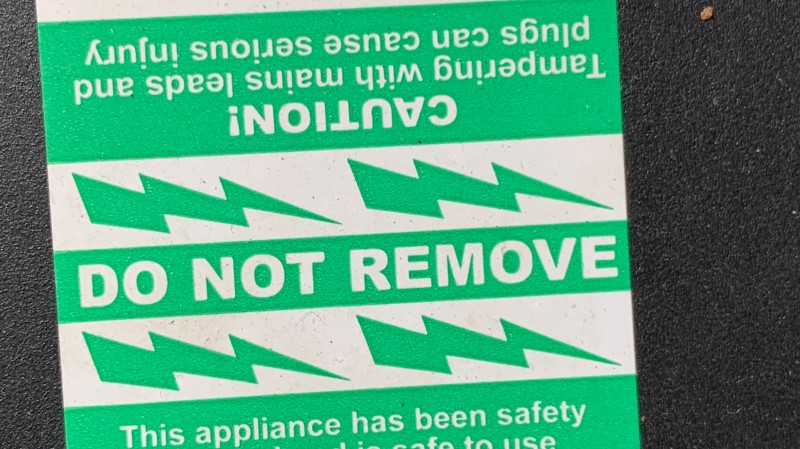

Many individuals and employers put stickers on the plugs of tested items to note the date of testing and recommendations for the date of the next test, based on the criteria below. Stickers are not a legal requirement, but it can make it easy to identify tested appliances and the date of that test.

How often do I need PAT?

The frequency with which equipment should be tested is down to the judgement of the competent person doing the testing and associated risk assessments. It will depend on many factors, such as:

- How frequently is the equipment used? Equipment that is used more often needs to be tested more often.

- Does the appliance get moved around a lot? Is it liable to be knocked or dropped during it is everyday use? If an office printer sits in the corner and is never moved, testing once every 2-5 years might be sufficient.

- Is the equipment used in high-risk environments? For example: dusty building sites, swimming pools, roof tops etc.

- How old is the equipment? Older equipment will be more prone to damage and needing repair.

- Has it been modified or repaired?

- Has it been misused in the past, or is it likely to be misused? For example, equipment accessible to the public in gyms, libraries etc.

- What Class is the appliance? Surrey Fire & Safety Ltd have a detailed table of how appliances are categorised and how this relates to the frequency of testing.

Summary

PAT testing is not a legal requirement for employers, the self-employed or landlords, however it has become one of the most commonly used procedures to ensure electrical equipment is safe and well maintained. A competent person can conduct PAT testing, and several companies offer training in the knowledge required. Class 1 appliances will generally require visual inspection as well as electrical tests of polarity, insulation and continuity. Class 2 appliances usually just need careful visual inspection. Testing of some appliances (Fixed Class 1 appliances) is best left to qualified electricians due to the need to isolate them from the mains power supply for a full test. For PAT testing to ensure the safety of electrical equipment, it is essential that good records are kept and a regime for testing adhered to.

If you are looking for help with any electrical issues, you may find some of these services useful:

Electricians

Get contact details for Electricians near to you. View the Feedback from other Customers to help you make an informed choice.

Electrical Reports

Find an Electrician to produce an Electrical report (sometimes known as an Electrical Installation Condition Report - or EICR) for a property.

Smart Home Technology

If you are looking for an Electrician to help with Smart Home Technology

Kitchen / Bathroom Electrics

If you are looking for an Electrician to help with Kitchen or Bathroom Electrics

LED Lighting

If you are looking for an Electrician to help with LED Lighting

Electric Heating Installation

If you are looking for an Electrician to install Electric Heating

Electric Vehicle Charging Point Installation

If you are looking for an Electrician to install an Electric Vehicle Charging Point

Security and Fire Alarms

If you need a fire or security alarm installing